Home / News / Installation and Benefits of Slewing Bearings for Sale

Installation and Benefits of Slewing Bearings for Sale

There are several different types of slewing bearings for sale, and we'll discuss the different features and benefits of each type. This article will also cover installation and price. Ultimately, we hope this article will help you find the right slewing bearing for your application. To get started, please contact us today. We'll be happy to answer any questions you may have. We're always happy to help!

price

The market for slewing bearings is experiencing massive competition, particularly in the GCC construction industry, where the prices have risen significantly. The price increases in slewing bearings in GCC countries have been brought down by increased domestic demand, owing to a large disparity between their costs and the global average. These price increases, however, are not sustainable in the long run. A recent World Bank report indicated that the cost of slewing bearings is likely to remain stable and increase in the coming years.

Infrastructural activities also benefit from slewing bearings. Elevators, escalators, and walkways all operate on bearings. For military and technical uses, large diameter slewing ring bearings are essential components in tank turrets, missile launchers, and precision radar antennae. Aerial lifts and hydraulic excavators are common business uses for slewing bearings. Health care applications include stretchers and medical sports equipment.

all types

Slewing bearings are a key component of large equipment and other infrastructural activities. They improve power transmission and load support and are generally employed in applications that require slow motion. The advantages of slewing bearings make them an ideal solution for heavy-duty applications requiring precision positioning and economy of envelope dimension. As the name suggests, slewing bearings are widely used in a variety of applications, including in construction, mining, agriculture, healthcare, and more.

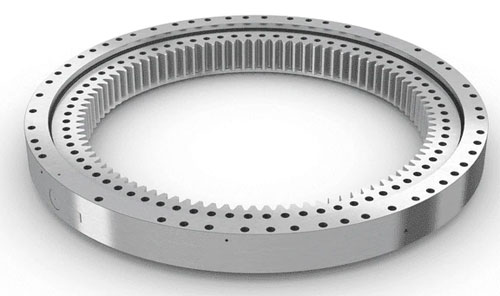

A slewing bearing consists of an inner ring and an outer ring that normally incorporates a gear. It provides optimal power transmission and a simple connection between adjacent machine components. Designed to accommodate a variety of load directions, slewing bearings are available in a wide range of designs and outside diameters ranging from 0,1 to eighteen meters. SKF, for example, manufactures both standard and customized slewing bearings and is also willing to custom-design slewing bearings to fit a specific application.

installation

The slewing bearings are installed in the slewing ring raceways at 90 degrees to the main load axis. The ring is rotated three times to ensure that the gear meshes with the main load axis. The deflection measured at the center of the slewing bearing gear and the pinion must be within the specified values. It is advisable to check the backlash of the slewing bearing gear with a measuring instrument of 0.1 mm precision grade. Then, apply the measured load and repeat the procedure at previously marked points. The measurement should also take into account the deflection of the supporting structure and the fasteners in the corresponding position.

The protective seals must be checked before the slewing bearings are installed. The bolts must be tightened properly, and the slewing bearing should be rotated to prevent any tight spots. The bolts should be retightened after every 100 hours of use, or when they begin to lose pre-load due to the structure settling. The slewing bearing should be tested annually for proper functioning.