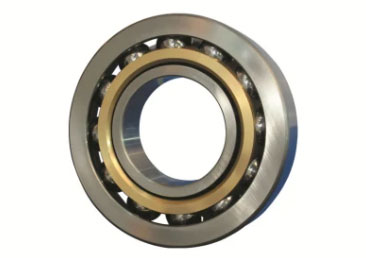

Single-row angular contact ball bearings

Single-row angular contact ball bearings are widely used in various industrial applications due to their high load-carrying capacity, high-speed operation, and ability to handle both radial and axial loads. These bearings have a unique design that allows the balls to be placed at an angle to the raceway, resulting in improved load distribution and reduced friction. In this article, we will provide a comprehensive guide to the design, applications, and maintenance of single-row angular contact ball bearings.

Design:

Single-row angular contact ball bearings consist of an inner ring, an outer ring, a cage, and a set of steel balls that move in deep grooves between the rings. The angle of contact between the balls and the raceway is typically 40 degrees, which provides optimal load distribution and reduced friction. These bearings are available in a range of sizes, shapes, and materials to meet various application requirements. Some of the key design factors to consider when selecting single-row angular contact ball bearings include load capacity, speed, temperature range, and lubrication requirements.

Applications:

Single-row angular contact ball bearings are used in a variety of industrial applications, including machine tool spindles, pumps, compressors, and automotive applications such as wheel bearings and steering systems. They are ideal for applications that require high-speed operation, precision, and low noise. These bearings can handle both radial and axial loads, making them suitable for applications with both types of loads.

Maintenance:

Proper maintenance is essential for ensuring the long service life of single-row angular contact ball bearings. Regular inspections can help detect early signs of wear and prevent catastrophic failures. Proper lubrication is critical for reducing friction and preventing premature wear. It is essential to use the correct type and amount of lubricant and to follow the manufacturer's recommendations for lubrication intervals. In addition, it is essential to keep the bearing clean and free of contaminants that can cause damage to the bearing surfaces.

Conclusion:

Single-row angular contact ball bearings are a versatile and reliable solution for a wide range of industrial and automotive applications. By understanding the design factors, applications, and maintenance requirements of these bearings, you can ensure their proper selection, installation, and maintenance, leading to long service life and optimal performance.

- Previous: Deep groove ball bearings

- Next: Precision Angular Contact Bearing 70 Series